Viscometer

Rotating viscometers, oscillating viscometers, Ubbelohde viscometers and viscometers according to ASTM D445 and ASTM 446 are important instruments for measuring the viscosity of liquids. Each of these viscometers has its specific properties and advantages to meet the different requirements of applications in industry and research.

The rotational viscometer measures the viscosity of liquids by rotating a cylinder or disc sensor in the liquid. The rotation of the cylinder or disc creates a flow in the liquid, the resistance of which is measured to determine the viscosity. Rotating viscometers are particularly suitable for measuring liquids with higher viscosities.

Oscillating viscometers, on the other hand, measure the viscosity of liquids by measuring the time it takes for a vibration to pass through the liquid. Oscillating viscometers are usually faster and easier to use than rotational viscometers and are therefore often used to measure low-viscosity liquids such as solvents or lubricating oils.

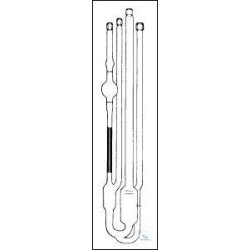

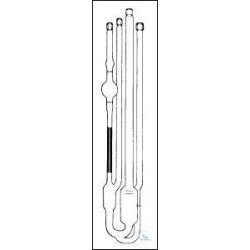

The Ubbelohde viscometer works with a glass tip that is immersed in the liquid. The liquid flows through the glass tip due to gravity and capillary forces. The time it takes to move a certain amount of liquid through the glass tip is measured to determine the viscosity. Ubbelohde viscometers are particularly suitable for measuring liquids with very low viscosity.

Viscosity measurements according to ASTM D445 and ASTM D446 are standardised test methods for determining the viscosity of liquids. ASTM D445 is a test method for determining the kinematic viscosity of liquids, while ASTM D446 is a test method for determining the dynamic viscosity of liquids. These test methods are widely used in various industries such as the chemical industry, the petroleum industry and the food industry.

Overall, rotational viscometers, oscillating viscometers, Ubbelohde viscometers and viscometers according to ASTM D445 and ASTM D446 offer a wide range of options for measuring the viscosity of liquids. The selection of the appropriate viscometer depends on the requirements of the application and the properties of the liquid to be measured.

Another important viscometer is the falling sphere viscometer. Here, viscosity is determined by measuring the falling time of a ball in the liquid. The ball falls through the liquid and the time it takes to travel a certain distance is measured. The viscosity is then calculated from the fall time and the size of the ball. The falling ball viscometer is particularly suitable for measuring viscous liquids such as varnishes, paints and adhesives. The falling ball viscometer is easy to use and requires no special training, making it a popular viscometer in industry. Another advantage of the falling sphere viscometer is that it is relatively inexpensive due to its simple design. It is therefore particularly suitable for applications where a fast, inexpensive and reliable viscosity measurement is required. However, it should be noted that the falling ball viscometer is not suitable for measuring very low viscosities, as the ball falls through the liquid too quickly and the measurement can become inaccurate. In this case, a vibrating viscometer or an Ubbelohde viscometer would be more suitable. Overall, the falling ball viscometer offers a simple, inexpensive and reliable way to measure the viscosity of viscous liquids. However, it is important to select the right viscometer for the particular application and the liquid to be measured in order to obtain accurate measurement results.